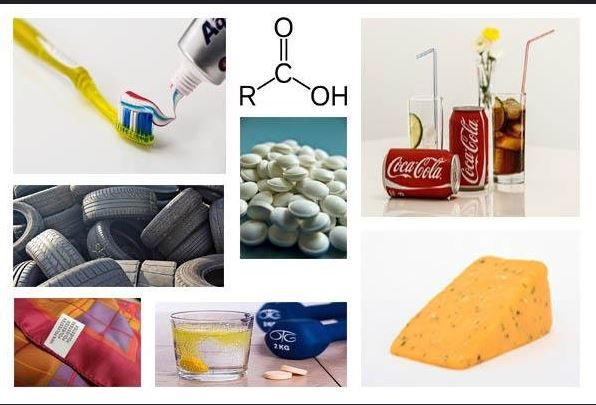

Innovating chemical recycling processes is crucial for improving sustainability and reducing waste in various industries. Advances in this field can help transform discarded chemicals into valuable resources, minimizing environmental impact. Here are effective strategies to innovate chemical recycling processes and drive progress in this essential area.

1. Implement Advanced Catalysis

Using advanced catalysts can significantly enhance chemical recycling efficiency. Catalysts speed up chemical reactions and make them more selective, which helps in breaking down complex materials into reusable components. By innovating chemical recycling processes with cutting-edge catalysts, you can improve the yield and quality of recycled products.

Chemical Recycling Processes

2. Develop Closed-Loop Systems

Closed-loop recycling systems recycle materials back into the same product without losing quality. By innovating chemical recycling processes to include closed-loop systems, you ensure that recycled chemicals are used repeatedly in the production cycle, reducing waste and resource consumption.

3. Explore Solvent-Based Recycling

Solvent-based recycling uses solvents to dissolve and separate chemical components for recovery. This method can be highly effective for recycling specific types of chemicals. Innovating chemical recycling processes with solvent-based techniques can increase the efficiency and versatility of recycling systems.

4. Integrate Machine Learning and AI

Machine learning and artificial intelligence (AI) can optimize chemical recycling processes by analyzing vast amounts of data to improve efficiency. These technologies can predict optimal conditions for reactions and identify patterns that enhance recycling performance. Innovating chemical recycling processes with AI helps in making data-driven improvements and accelerating advancements.

5. Utilize Enzyme-Based Recycling

Enzymes are biological catalysts that can break down complex chemical structures into simpler forms. Enzyme-based recycling processes are often more environmentally friendly. By innovating recycling processes to include enzyme-based methods, you can enhance the efficiency and sustainability of recycling.

6. Apply Hydrothermal Processes

Hydrothermal recycling involves using high-temperature and high-pressure water to break down materials. This process can be highly effective for recycling plastics and other complex chemicals. Innovating recycling processes with hydrothermal techniques can improve the efficiency and range of materials that can be recycled.

7. Adopt Plasma Arc Technology

Plasma arc technology uses high-temperature plasma to decompose chemical substances into their basic elements. This method is effective for recycling hazardous and non-recyclable materials. By innovating recycling processes with plasma arc technology, you can handle a broader range of materials and enhance recycling capabilities.

8. Develop Hybrid Recycling Systems

Hybrid recycling systems combine multiple technologies to achieve better results. For example, integrating mechanical and recycling processes can enhance efficiency. Innovating chemical recycling processes with hybrid systems allows for more comprehensive and flexible recycling solutions.

9. Focus on Process Optimization

Optimizing existing recycling processes can lead to significant improvements in efficiency and cost-effectiveness. By innovating recycling processes with a focus on optimization, you can enhance reaction conditions, reduce energy consumption, and increase the overall effectiveness of recycling.

10. Enhance Material Sorting Techniques

Effective material sorting is crucial for successful recycling. Advanced sorting technologies can separate different types of materials more accurately. Innovating chemical recycling processes with improved sorting techniques ensures that the right materials are processed, leading to better recycling outcomes.

11. Promote Collaboration with Industry Partners

Collaboration between companies, research institutions, and government agencies can drive innovation in chemical recycling. By innovating recycling processes through partnerships, you can share knowledge, resources, and technologies to accelerate progress and improve recycling solutions.

12. Invest in Research and Development

Investing in research and development (R&D) is essential for discovering new methods and technologies for recycling. By innovating chemical processes through R&D, you can stay at the forefront of technological advancements and implement cutting-edge solutions.

13. Implement Sustainable Practices

Sustainable practices in chemical recycling ensure that processes are environmentally friendly and resource-efficient. This includes reducing emissions, minimizing waste, and using renewable energy sources. Innovating chemical recycling processes with a focus on sustainability helps in creating a greener and more efficient recycling system.

14. Explore Modular Recycling Systems

Modular recycling systems are flexible and can be adapted to different types of materials and processes. By innovating recycling processes with modular systems, you can create scalable and customizable solutions that meet various recycling needs.

15. Educate and Train Personnel

Training personnel in the latest recycling technologies and techniques is crucial for successful implementation.

Conclusion

Innovating chemical recycling processes involves leveraging advanced technologies, optimizing existing systems, and focusing on sustainability. By adopting these strategies, you can enhance the efficiency and effectiveness of recycling, contribute to environmental conservation, and drive progress in the field. Embrace innovation to transform chemical recycling and create a more sustainable future.