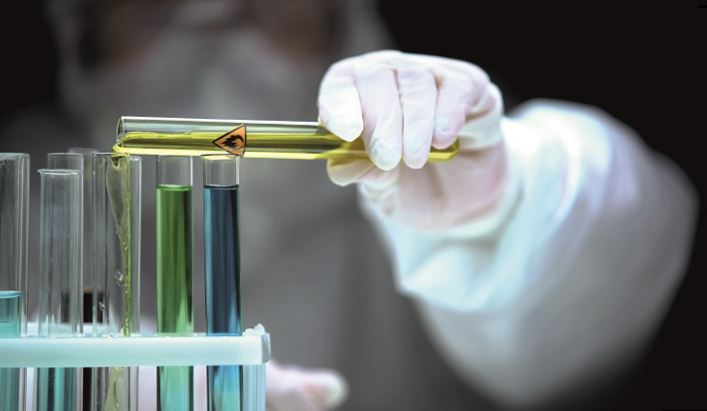

Corrosive substances, such as strong acids and bases, can cause severe damage to skin, eyes, respiratory system, and materials they contact. These chemicals react with living tissue and materials, causing burns, respiratory problems, and degradation of materials. Understanding the specific hazards associated with each corrosive substance is crucial for implementing effective protective measures.

Protective Measures for Working with Corrosive Substances

Personal Protective Equipment (PPE)

Using appropriate personal protective equipment (PPE) is critical when working with corrosive substances. Essential PPE includes chemical-resistant gloves, goggles or face shields, lab coats, and respiratory protection. The choice of PPE should be based on the specific chemical and its concentration. Regular inspection and replacement of PPE ensure its integrity and effectiveness in providing protection.

Engineering Controls

Implementing engineering controls can significantly reduce the risk of exposure to corrosive substances. Use fume hoods, local exhaust ventilation, and containment systems to prevent the spread of harmful vapors and splashes. Proper maintenance and regular testing of these controls ensure they function correctly, providing ongoing protection for workers.

Safe Handling Procedures

Adopting safe handling procedures minimizes the risk of accidents when working with corrosive substances. Always add acids to water, not water to acids, to prevent violent reactions. Use appropriate tools and equipment designed for handling corrosive materials, and never pipette by mouth. Label all containers clearly, and ensure that only trained personnel handle these substances.

Workplace Hygiene Practices

Maintaining good hygiene practices in the workplace helps prevent accidental exposure to corrosive substances. Wash hands and any exposed skin thoroughly after handling chemicals. Avoid eating, drinking, or touching the face in areas where corrosive substances are used. Regularly clean work surfaces and equipment to remove any residue.

Proper Storage Solutions

Storing corrosive substances correctly is crucial to prevent leaks, spills, and dangerous reactions. Store these chemicals in appropriate containers made from materials resistant to corrosion. Ensure storage areas are well-ventilated, cool, and away from incompatible substances. Use secondary containment to catch any leaks or spills and label all storage areas clearly.

Emergency Response Preparedness

Preparing for emergencies is essential when working with corrosive substances. Equip work areas with safety showers, eyewash stations, and spill kits containing neutralizing agents. Train employees in emergency response procedures, including first aid and evacuation plans. Regular drills ensure everyone knows how to respond quickly and effectively in case of an incident.

Training and Education

Regular training and education for employees on the hazards of corrosive substances and proper safety measures are vital. Training programs should cover the use of PPE, safe handling practices, emergency response, and proper storage. Keeping employees informed about the risks and safety protocols helps reinforce a culture of safety in the workplace.

Regular Safety Audits

Conducting regular safety audits and inspections helps identify potential hazards and ensure compliance with safety protocols. Audits should include checks on PPE availability, the functioning of engineering controls, and adherence to safe handling procedures. Documenting and addressing any findings from these audits support continuous improvement in safety practices.

Conclusion

Protecting against the hazards of corrosive substances requires a comprehensive approach that includes using proper PPE, implementing engineering controls, following safe handling and hygiene practices, and ensuring proper storage. Regular training, emergency preparedness, and safety audits further enhance protection. By adhering to these measures, workplaces can maintain a safe environment and protect employees from the dangers of corrosive substances.