Proper storage of hazardous chemicals is essential for ensuring safety, preventing accidents, and maintaining compliance with regulatory requirements. Mishandling these substances can lead to leaks, spills, fires, or toxic exposures, posing serious risks to health and the environment. Following established guidelines for storing hazardous chemicals helps mitigate these dangers and promotes a safer working environment.

Storage Guidelines for Hazardous Chemicals

Identifying and Labeling Chemicals

The first step in safely storing hazardous chemicals is to correctly identify and label them. Each chemical should have a clear, durable label that includes its name, hazards, and safety precautions. Utilizing the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals ensures consistency and clarity. Proper labeling helps workers quickly recognize the substances they are handling and understand the associated risks.

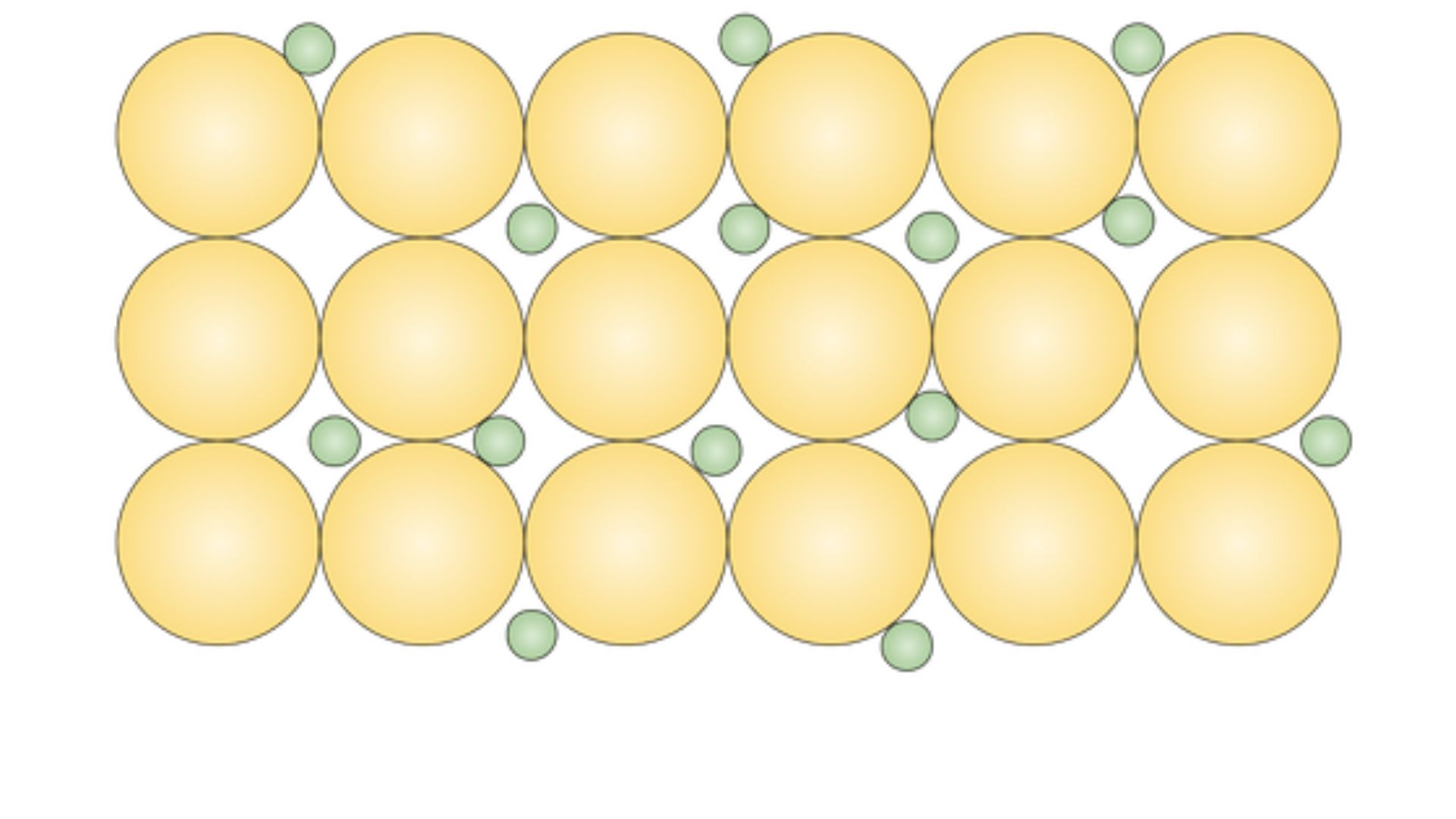

Segregation of Chemicals

Segregating chemicals based on their compatibility is crucial to prevent dangerous reactions. Incompatible chemicals can react violently if they come into contact, causing fires, explosions, or the release of toxic gases. Store acids separately from bases, oxidizers away from flammable substances, and reactive chemicals isolated from each other. Utilizing designated storage cabinets and areas for different classes of chemicals helps maintain safe segregation.

Proper Storage Conditions

Storing hazardous chemicals under appropriate conditions is vital for maintaining their stability and safety. Temperature, humidity, and light can all affect the integrity of chemicals. Most chemicals should be stored in a cool, dry place away from direct sunlight. Flammable liquids should be kept in flammable storage cabinets, while volatile substances may require ventilation. Regularly monitoring and maintaining these conditions helps prevent chemical degradation and potential hazards.

Use of Safety Cabinets and Containers

Using safety cabinets and containers specifically designed for hazardous chemicals enhances storage safety. Flammable storage cabinets, corrosive storage cabinets, and explosion-proof refrigerators provide additional protection against fire, leaks, and spills. Ensure that all containers are made from compatible materials and are in good condition, with secure, tightly fitting lids to prevent accidental releases.

Accessibility and Organization

Organizing chemical storage areas for easy access and clear organization reduces the risk of accidents. Store chemicals at eye level or below to minimize the chance of spills when retrieving containers. Avoid overcrowding shelves and ensure that chemicals are not stored on the floor, where they can be easily knocked over. Clearly label storage areas and keep an up-to-date inventory of all chemicals to facilitate safe handling and quick identification.

Safety Data Sheets (SDS)

Maintaining and regularly updating Safety Data Sheets (SDS) for all hazardous chemicals is a critical component of safe storage practices. SDS provide detailed information on the properties, hazards, handling, and emergency procedures for each chemical. Ensure that SDS are readily accessible to all employees, either in physical form or through a digital system, and that workers are trained to use them effectively.

Training and Education

Providing comprehensive training and education on hazardous chemical storage is essential for ensuring that all employees understand the risks and proper handling procedures. Training should cover identification, labeling, segregation, storage conditions, and emergency response. Regular refresher courses and drills help reinforce safe practices and keep safety at the forefront of workers’ minds.

Spill and Emergency Response

Preparing for spills and emergencies is a crucial aspect of hazardous chemical storage. Equip storage areas with spill kits, personal protective equipment (PPE), and emergency shower and eyewash stations. Establish clear procedures for responding to spills, leaks, and other emergencies, and ensure that all employees are familiar with these protocols. Prompt and effective response to incidents can significantly reduce the impact of hazardous chemical releases.

Compliance and Inspections

Regular inspections and compliance checks help maintain safe storage conditions and adherence to regulatory requirements. Conduct routine inspections of storage areas, containers, and safety equipment to identify and address potential hazards. Stay informed about relevant regulations and guidelines from agencies such as OSHA, EPA, and local authorities, and ensure that your storage practices meet or exceed these standards.

Conclusion

Proper storage of hazardous chemicals is a fundamental aspect of workplace safety. By following guidelines for identification, segregation, storage conditions, and emergency preparedness, you can significantly reduce the risks associated with hazardous substances. Investing in proper training, equipment, and compliance measures ensures a safe and secure environment for all employees and helps protect health and the environment.