Ensuring proper ventilation when using chemicals is vital for maintaining a safe working environment. Inadequate ventilation can lead to dangerous levels of chemical fumes, which can pose serious health risks. Here’s a comprehensive guide to ensuring effective ventilation when using chemicals.

1. Understand the Importance of Ventilation

Proper ventilation when using chemicals is crucial to prevent the buildup of harmful vapours and gases. Good ventilation helps dilute and remove toxic substances from the air, reducing the risk of exposure and maintaining a safe workspace. It also helps in controlling temperature and humidity levels, which can affect chemical reactions.

Proper Ventilation When Using Chemicals

2. Use Local Exhaust Ventilation

Local exhaust ventilation systems capture and remove contaminants at their source. Fume hoods and local exhaust fans are examples of effective systems for maintaining proper ventilation when using chemicals. Position these devices close to the chemical source to effectively capture fumes and prevent them from spreading.

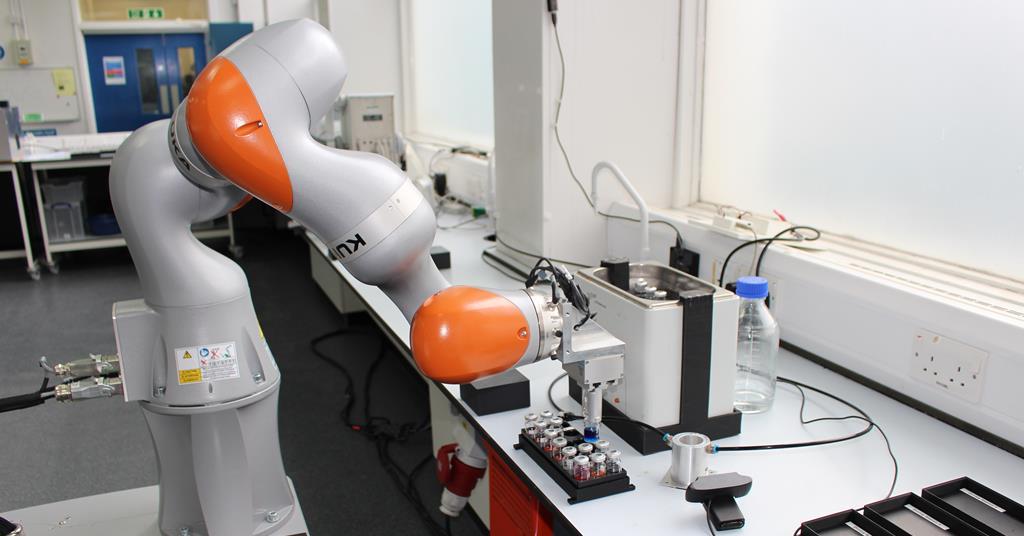

3. Install Proper Fume Hoods

Fume hoods are essential for maintaining proper ventilation when using chemicals in laboratories. They provide a controlled environment where chemical vapours can be safely contained and removed. Ensure that fume hoods are properly maintained and tested regularly to ensure their effectiveness.

4. Ensure Adequate Airflow

To ensure ventilation when using chemicals, make sure your workspace has adequate airflow. This can be achieved by using fans, and air conditioning systems, and ensuring that doors and windows are properly adjusted to promote cross-ventilation. Proper airflow helps in diluting and dispersing chemical fumes.

5. Utilize Exhaust Fans

Exhaust fans help maintain proper ventilation when using chemicals by removing contaminated air from the workspace. Place exhaust fans in areas where chemical handling occurs to ensure that fumes are effectively vented outside. Regularly check and maintain these fans to ensure they are functioning correctly.

6. Conduct Regular Air Quality Checks

Regularly check the air quality in areas where chemicals are used. Use air monitors to detect the presence of harmful vapours and ensure that ventilation when using chemicals is sufficient. If high levels of contaminants are detected, adjust your ventilation systems accordingly.

7. Implement Proper Storage Solutions

Store chemicals properly to prevent accidental releases of fumes. Use sealed containers and store volatile chemicals in well-ventilated areas. Proper storage solutions are an important part of maintaining effective ventilation when using chemicals.

8. Educate and Train Staff

Ensure that all staff members are trained on the importance of ventilation when using chemicals. Provide training on how to use ventilation systems properly and how to recognize signs of inadequate ventilation. Regular training helps in maintaining a safe environment and ensures that everyone understands the procedures.

9. Use Personal Protective Equipment (PPE)

While proper ventilation when using chemicals is crucial, using Personal Protective Equipment (PPE) can provide an additional layer of safety. Wear appropriate masks, gloves, and goggles to protect yourself from exposure, especially when working with chemicals in less-than-ideal ventilation conditions.

10. Regular Maintenance of Ventilation Systems

Ventilation systems need regular maintenance to function effectively. Check and replace filters, clean ducts, and ensure that all components are working correctly. Regular maintenance ensures that your ventilation when using chemicals remains effective over time.

11. Design Workspaces for Optimal Ventilation

When setting up a workspace, design it with ventilation when using chemicals in mind. Ensure that the layout promotes good airflow and allows for the effective placement of ventilation equipment. A well-designed workspace can significantly enhance the effectiveness of your ventilation systems.

12. Implement a Ventilation Plan

Develop a detailed ventilation plan that outlines how to manage chemical fumes and ensure adequate ventilation. The plan should include the types of ventilation systems in use, their locations, maintenance schedules, and emergency procedures. A well-thought-out plan helps in managing ventilation effectively.

13. Monitor Ventilation Performance

Continuously monitor the performance of your ventilation systems. Use indicators such as air velocity and flow rate to ensure that the systems are operating correctly. Monitoring helps in identifying issues early and ensuring that ventilation when using chemicals is maintained at optimal levels.

14. Consider the Use of Chemical Neutralizers

For areas where ventilation alone may not be sufficient, consider using chemical neutralizers. These products can help in neutralizing harmful fumes and improving overall air quality. While not a substitute for proper ventilation, they can be an additional measure to enhance safety.

15. Regularly Review and Update Safety Procedures

Regularly review and update your safety procedures to ensure they align with current best practices for ventilation when using chemicals. Stay informed about new regulations and advancements in ventilation technology to keep your practices up-to-date and effective.

Conclusion

Ensuring proper ventilation when using chemicals is essential for maintaining a safe and healthy working environment. By using local exhaust ventilation, installing fume hoods, ensuring adequate airflow, and following best practices, you can effectively manage chemical fumes and protect yourself and others from potential hazards. Regular maintenance, staff training, and proper storage also play crucial roles in effective ventilation.